HOME PRODUCTS LAB DIVISION

Fedegari Lab Division latest innovation is a Lab Glassware Washer that capitalizes the experience done with FOWS-series of washers in the pharmaceutical industry.

The power of steam: a cost-effective cleaning

The new FGW Lab Glassware Washer uses a steam generator to improve washing performances. Steam has an optimized emollient effect on greasy and sticky dirt. In addition, steam is able to access hard-to-reach areas and therefore clean thoroughly. Moreover the use of steam can significantly reduces operating costs: this really eco-friendly solution allows to minimize the need of detergents as well as water consumption, lowering the running costs per cycle.

A conductivity meter placed on the FGW drain is capable to detect the water purity, helping to terminate the process as soon as the desired set-point is reached thus further reducing water and other utilities consumption of the washer.

The cleaning process is constantly supervised: dedicated probes monitoring the temperature of the air/water and of the steam in chamber. Fedegari Glassware Washer has an internal LED lamp that remains operative during the whole cycle: in case of alarm evident signals are displayed by color change.

DESIGN AND TECHNICAL FEAUTURES

The piping, as any other equipment manufactured by Fedegari, has a rigorous sanitary finishing. The FGW glassware washer is equipped with custom-made and modular internal trays, connected to the hydraulic system. The external trolleys are fully compatible with those of the FOB5 autoclave.

KEY BENEFITS

- Steam improves washing performances.

- Thema4Lab.

- Steam as Eco-friendly solution.

- Energy saving function.

- Customizable internal rack.

- Trolleys and trays fully compatible with FOB5 series.

- Sanitary components and CIP to ensure a perfect washing.

- GLP compliance.

COMPLIANCE TO

- PED Directive 2014/68/UE – Pressure equipment**

- Machine Directive Macchine 2006/42/EC

- EMC Directive 2014/35/UE

- LVD Directive 2006/95/UE

STANDARD

- EN ISO 12100 Safety of machinery – General principles for design – Risk assessment and risk reduction

- EN ISO 13857 Safety of machinery – Safety distances to prevent hazard zones being reached by upper and lower limbs

- EN ISO 13849-1 Safety of machinery – Safety-related parts of control systems – Part 1: General principles for design

- EN IEC 60204-1 Safety of machinery – Electrical equipment of machines – Part 1: General requirements

- EN IEC 61326-1 Electrical equipment for measurement, control and laboratory use – EMC requirements – Part 1: General requirements

- EN 61010-1 Safety requirements for electrical equipment for measurement, control, and laboratory use – Part 1: General requirements

- EN 61010-2-040 Safety requirements for electrical equipment for measurement, control, and laboratory use – Part 2-040 Particular requirements for sterilizers and washer-disinfectors used to treat medical materials

Standard compliance for non-EU countries

United States of America (USA)

- ASME (American Society of Mechanical Engineers) S Stamp**

- UL 508 A Standard for Industrial Control Equipment

- NPFA 70 National Electrical Code (NEC

- NPFA 79 Electrical Standard for Industrial Machinery

People’s Republic of China

- SELO – Chinese Safety Regulation for Pressure Vessel**

Russian Federation

- TR CU 032 On the safety of equipment operating under excessive pressure**

- TR CU 010 Machinery Directive

Brazil

- NR 13 Boilers and Pressure Vessel**

Malaysia

- Department of Occupational Safety and Health (DOSH)**

Singapore

- Ministry of Manpower (MOM)**

** note: applicable only with option KX10 Electrical Steam Boiler

VIDEO

See how to integrate the FGW Lab Glassware Washer with your FOB5 Horizontal Steam Sterilizer.

DOWNLOAD

RELATED PRODUCTS

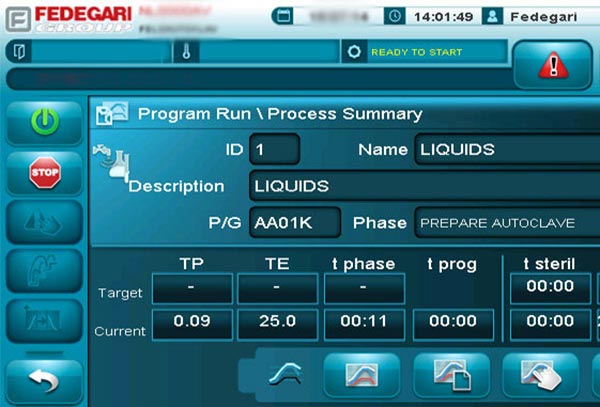

Thema4Lab

The FGW series is equipped with Thema4Lab process controller, engineered and pre-validated by Fedegari according to GAMP5. Thema4Lab is the most advanced process controller for lab applications, based on a wide library of phase groups, developed by Fedegari thanks to its experience with the highest standards in the pharmaceutical industry.

Thanks to the Thema4Lab process controller you can manage both FGW and FOB5, creating a true Fedegari environment in your lab.