HOME NEWS

“The current COVID-19 crisis is fundamentally changing our reality with 81% expecting a negative effect on their workplace as a result. A rapid response with innovation to help our customers and communities is more critical now than ever,”

Kevin Dallas, CEO and President of Wind River.

A global leader with nearly four decades of experience powering the safest, most secure mission-critical systems in the world, Wind River is opening up access to its IP and expertise for the industry to leverage. The access is for companies manufacturing medical, 5G network, and industrial automation equipment that support the global battle against COVID-19. This includes Wind River customers like Draeger, GE Healthcare, and Fedegari Autoclavi, among others that are manufacturing massive quantities of life-saving products, such as ventilators, patient monitors, and medical instrumentation devices.

ABOUT WIND RIVER

Wind River is a global leader in delivering software for the intelligent edge. The company’s technology has been powering the safest, most secure devices in the world since 1981 and is found in more than 2 billion products. Wind River offers a comprehensive portfolio, supported by world-class global professional services and support and a broad partner ecosystem. Wind River software and expertise are accelerating digital transformation of critical infrastructure systems that demand the highest levels of safety, security, performance, and reliability.

Learn more at www.windriver.com.

SOFTWARE & TECHNICAL SERVICES

For qualified companies, Wind River is donating software and services from its industry-leading portfolio for the intelligent edge. The actions Wind River is taking will address the significant challenges created by the pandemic, such as limited access to labs with appropriate hardware for development and testing, delays in the supply chains that put development timelines at risk, and barriers to innovation.

For a limited time, the company is offering the following tools, software, and services, which will be especially critical given the drastically increased number of workforces at home under pressure to design, develop, and deploy systems.

“In moments of seismic change, Wind River is committed to helping the industry navigate and adapt to a challenging new climate in any way we can, and it is essential for us to step up and rally together in order to battle this pandemic.” explained Dallas, CEO and President of Wind River.

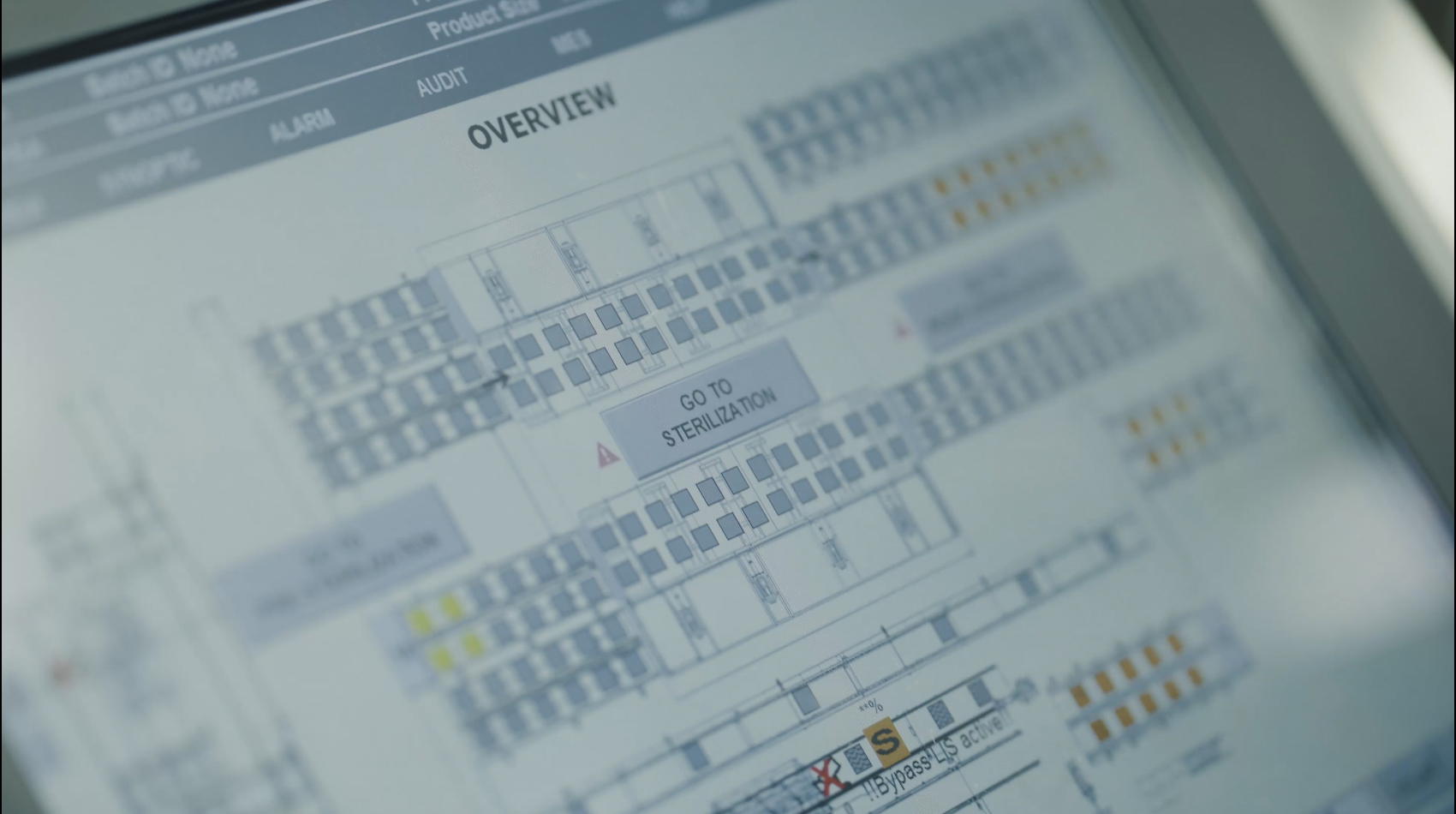

FEDEGARI PROCESS CONTROLLER

Powered by the Wind River platform, Thema4 is able

to provide a wide range of control, visualization, and

reporting functionalities. It also allows a high degree of

customization and communication with machine I/Os and

other external devices.

Want to learn more about our process equipment?