HOME PRODUCTS INDUSTRIAL DIVISION

With the FCDV bio decontamination unit you can bring inside the clean rooms all those products and instruments that cannot be thermally sterilized. Surface bio-decontamination of the load is carried out with vaporized hydrogen peroxide – H2O2.

Among the most reliable sporicidal agents, vaporized hydrogen peroxide (H2O2) is nowadays one of the most popular: its antibacterial, antimycotic and antiviral properties are well known and scientifically documented.

This solution is becoming increasingly relevant as the regulators shift their focus away from traditional moist- and dry-heat sterilization processes to address all other bioburden risks. Moreover, Fedegari has applied the Quality-by-design concept to the development of this innovative process equipment, in order to meet the current approach required by the EMA and FDA.

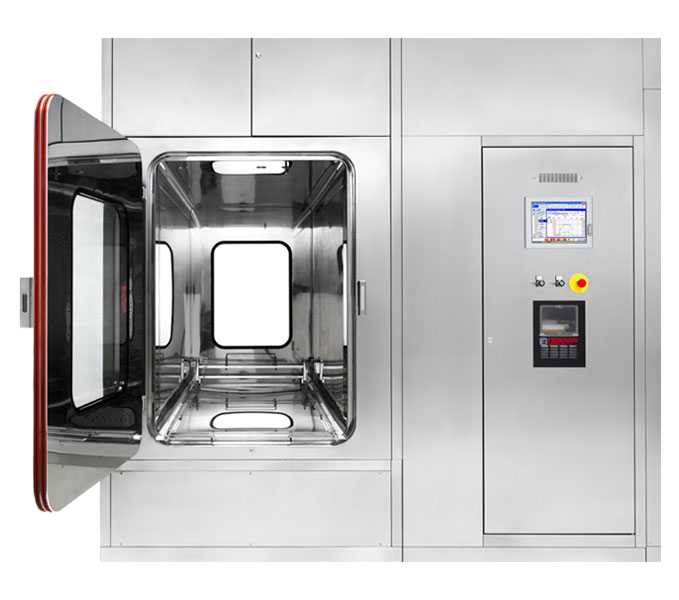

DESIGN & TECHNICAL FEATURES

- Stainless steel AISI 316L chamber, polished to strict sanitary standards (Ra <0.4 μm).

- Doors are made of AISI 316L stainless steel with a central glass panel

- 100% air-tight guaranteed: thanks to two separate inflatable gaskets seating in two slots mechanically machined all around the door with an additional leak-monitoring system.

- Direct control of hydrogen peroxide in the chamber.

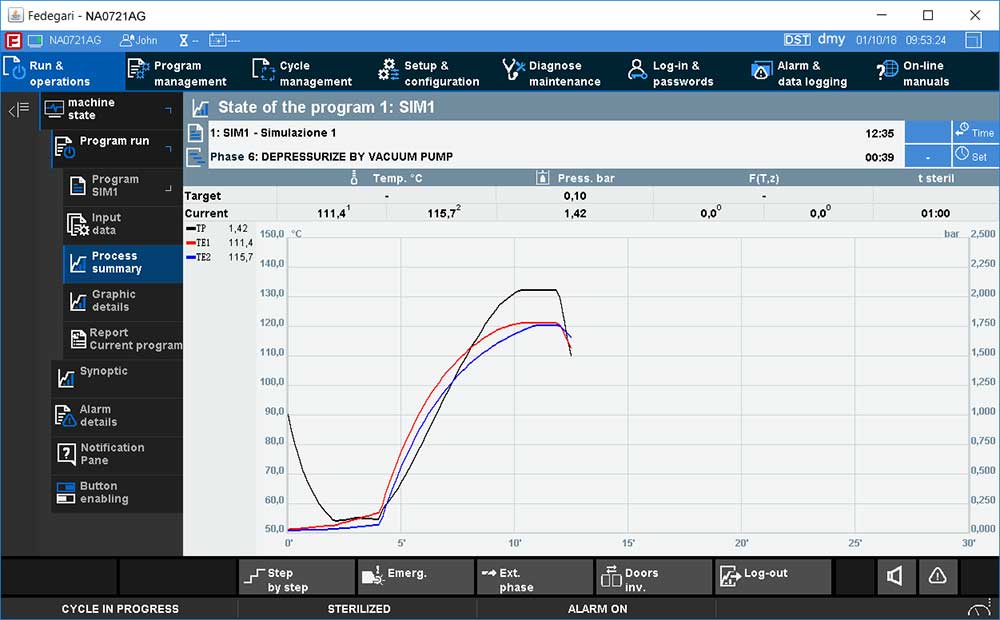

- Optimized process: surface bio decontamination is achieved in 30 minutes.

- Fedegari hydrogen peroxide vaporizer with control loop (PID based), which provides superior reliability and repeatability for easier validation.

- Great flexibility: FCDV can be used as a pass-through hatch aired with synchronized doors and pressure control.

KEY BENEFITS

- Process optimization: surface bio-decontamination in 30 min.

- Reliability: FHPV hydrogen peroxide vaporizer totally engineered and manufactured by Fedegari.

- Flexibility: the unit can be used as a pass-through hatch aired with synchronized doors and pressure control.

- Easy validation & integration: all processes managed by Thema4 process controller.

COMPLIANT TO

- European directives: 2014/30/EU – electromagnetic compatibility (EMC), 2014/35/EU – Low tension equipment (LVD), 2006/95/EC – Safety of machinery (MD)

- European standards: EN 55011, EN IEC 61000-4-2, EN IEC 61000-4-4, EN IEC 60204-1

- FDA: compliance for non metallic component in contact with process fluids

- GMP

- GAMP5

- 21 CFR Part 210, 211 e 11

- UL 508A

- NFPA-79

- ASME BPE

Optional

- US electrical norms: NFPA 70 – National electrical code, UL 61010-1 – Safety requirement for electrical equipment for measurement, control and laboratory use – Part 1: general requirements.

Want to know more about our certifications? Please visit the dedicated section or do not hesitate to contact us.