HOME PRODUCTS INDUSTRIAL DIVISION

FOD ovens, such as autoclaves, run batch processes and are the ideal solution for the sterilization of all those production lines in which the variability of products, batches and formats do not allow the use of continuous sterilizers such as tunnels. FOD ovens main advantage lies on its particle contamination class assurance.

Fedegari guarantees the contamination level to remain under the established standards values for ISO class according to ISO 14644-1. This accuracy is verified also during the most critical phases such as heating and cooling, when the thermal expansion of the filters may release a great amount of particles.

Particulate contamination control originates from complex fluid dynamic studies and a close collaboration with Camfil, the world’s most respected filter manufacturer, with whom Fedegari works at the development of high-temperature filters.

DESIGN & TECHNICAL FEATURES

- Sterilizing chamber: sealed welding, made of 304 (optional 316L) stainless steel 1,5 mm thick.

- Single-leaf flush door on both sides, internal surface in 304 (optional 316L) stainless steel.

- Thermal isolation in compliance with Euroclass A1 in accordance with EN 13501-1, ensuring the operator’s adequate safety of use at the chamber operating temperature of 250°C.

- Electric heating through AISI 321 stainless steel heating elements, assembled on a sliding frame for easy removal and maintenance.

- Electrical heaters are covered with tubes in Incoloy 800 (nickel-iron-chrome superalloy) providing high-temperature resistance and resistance to oxidation, carburization and other types of high-temperature corrosion.

- Electric centrifugal fans with sealed bearings of special type for high temperature to facilitate air circulation.

- Cooling by 304 stainless steel heat exchanger.

- Continuous automatic control and regulation of pressurization of the depyrogenation chamber.

- Continuous filtering of air in the sterilizing chamber, thanks to a system composed by 4 HEPA filters.

- 5 RTD PT100 temperature probes.

- Safety thermometer on non sterile front to prevent door opening if chamber temperature exceeds set value.

- Stainless steel port for validation probe positioned on not sterile side.

KEY BENEFITS

- Process performance particle contamination.

- Temperature uniformity process repeatability.

- The use of Fedegari standard components guarantees savings in training and maintenance thanks to standardized procedures.

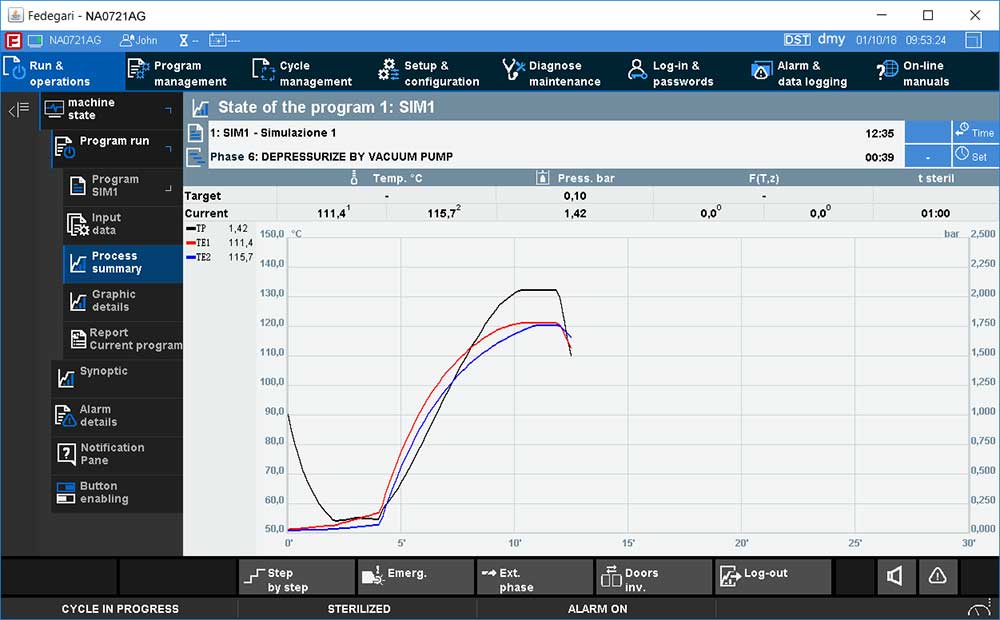

- Thema4 process controller pre-validated by Fedegari according to GAMP5.

COMPLIANT TO

European directives:

- 2006/42/CE Direttiva Macchine,

- 2014/30/EU Direttiva Compatibilità elettromagnetica (EMC),

- 2014/35/EU Dispositivi a bassa tensione (LVD),

European standards:

- EN ISO 12100,

- EN ISO 13857,

- EN ISO 13849-1,

- EN 60204-1

- EN 55011

- EN IEC 61000-4-2,

- EN IEC 61000-4-4,

- EN 61010-1,

- EN 61010-2-040,

- EN 61000-6-2,

- EN 61000-6-4,

- USA electrical standards: NFPA 70, NFPA 79, UL 508A UL 61010-1

- FDA: compliance for non metallic component in contact with process fluids

- GMP

- GAMP5

- 21 CFR Part 210, 211 e 11

- ASME BPE

Want to know more about our certifications? Please visit the dedicated section or do not hesitate to contact us.