HOME PRODUCTS INDUSTRIAL DIVISION

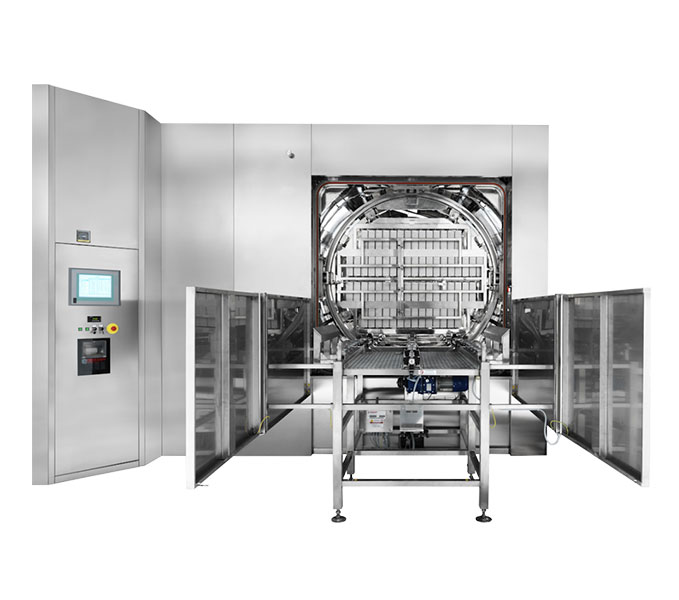

FOW Superheated Water sterilizers are able to perform counterpressure sterilization of large volume parenteral solutions through a superheated water spray system.

In compliance with cGMP and FDA standards for LVP products, FOW autoclaves are suitable for treating loads in containers that may be deformed due to the difference in pressure between the chamber and the container itself.

Where the product is liable to separation or for accelerating thermal transition phases, the whole load can be rotated during the entire sterilization process.

- Process optimization: The process is faster than the air-steam sterilization process. FOW is also an ideal sterilizer for <105 °C processing.

Wet loads can be overcome using on automated drying extension with the installation of specific drying solutions downstream of the sterilization chamber.

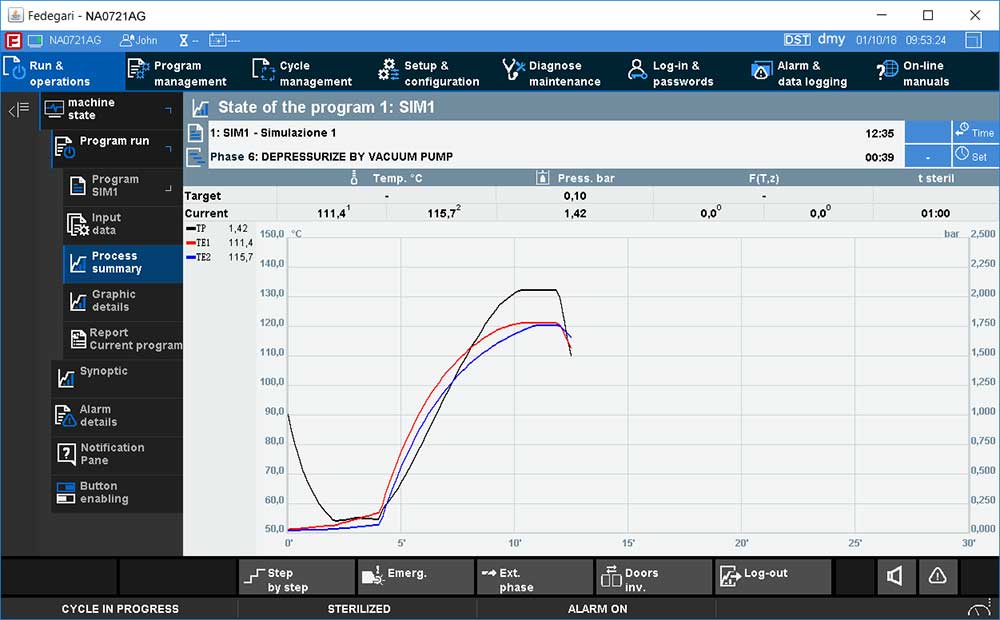

- Easy validation & integration:Thema4 process controller is pre-validated according to GAMP5 and in compliance with 21 CFR Part 11, thus resulting in shortest qualification time and minimizing project risks. Open system architecture that can be integrated with SCADA system and other Fedegari machines.

- Highest productivity: Fedegari R&D laboratory is available to develop the best treatment solution for your specific needs. We run tests with different loads and requirements.

TECHNICAL FEAUTURES

- FOW superheated water sterilizer is equipped with 316Ti – 1.4571 (316L – 1.4404 upon request) stainless steel chamber.

- Besides the standard versions from 830 to 14.800 liters, loading capacity is fully customizable according to customer needs. Le misure della camera sono comunque modificate e realizzate a seconda della necessità del cliente.

- Chamber internal surface mechanically polished with a roughness Ra <0,4 μm.

- One or two doors with vertical or hinged opening systems to cope with available space in the smartest possible way.

- 5 RTD PT100 probes for temperature control (2 fixed – in the filter and discharge – and 3 flexible for the load).

- Automatic sterilization of the air filter with fixed RTD PT100 temperature probe.

- 2 ports for validation probes.

- Fedegari exclusive patented door gaskets that assure 100% tightness. These gaskets are FDA compliant and optionally also USP Class VI compliant.

- Piping and valves in 316L – 1.4435 and 316L – 1.4404 stainless steel.

APPLICATION FIELDS

- Sterilization of parenteral solutions, liquids in sealed containers not deformable (eg. glass vials) and liquids in heat sensitive sealed containers (eg. plastic bags or bottles).

- Terminal sterilization of pre-filled syringes (PFSs)

SPECIAL APPLICATIONS

ROTATING LOAD

The load is held in rotation thanks to a special rotating drum inside the chamber. The rotation drum has a magnetic coupling and is adjustable in speed, direction of rotation and intermittently. This system finds application in the treatment of suspensions and emulsions and ensures a better performance of the tightness tests for ampoules under vacuum and a more homogeneous heat transmission in the load.

VIDEO

Robotic handling with FOW for the pharmaceutical industry.

STANDARDS COMPLIANCE

European directives:

- 2006/42/CE Safety of machinery,

- 2014/30/UE Electromagnetic compatibility (EMC),

- 2014/35/UE Low tension equipment (LVD),

European standards:

- EN ISO 12100,

- EN ISO 13857,

- EN ISO 13849-1,

- EN 60204-1

- EN 55011

- EN IEC 61000-4-2,

- EN IEC 61000-4-4,

Pressure vessel:

- European Directive: 2014/68/UE Annex III module H and construction code AD-2000

- ASME: Stamp R, Stamp S, Stamp U

- Chinese standard: SELO

- Swiss standard: SR 930.114

- Russian standard: CU TR 032

- PD 5000 code specification for unfired, fusion-welded pressure vessels

- Brasil: NR-13

- Japan: JIS C 8265, JIS B 8201, JIS Z 3107, JIS B 8284, JIS B 8266, JIS 2220

- South Africa: SANS 347

Other compliance:

- USA electrical standards:NFPA 70, NFPA 79, UL 508A UL 61010-1

- Canadian electrical standards: CAN/CSA C22.1 and CSA C22.2

- FDA: compliance for non-metallic component in contact with process fluids

- GMP

- GAMP5

- 21 CFR Part 210, 211 e 11

Want to know more about our certifications? Please visit the dedicated section or do not hesitate to contact us.