The Challenge

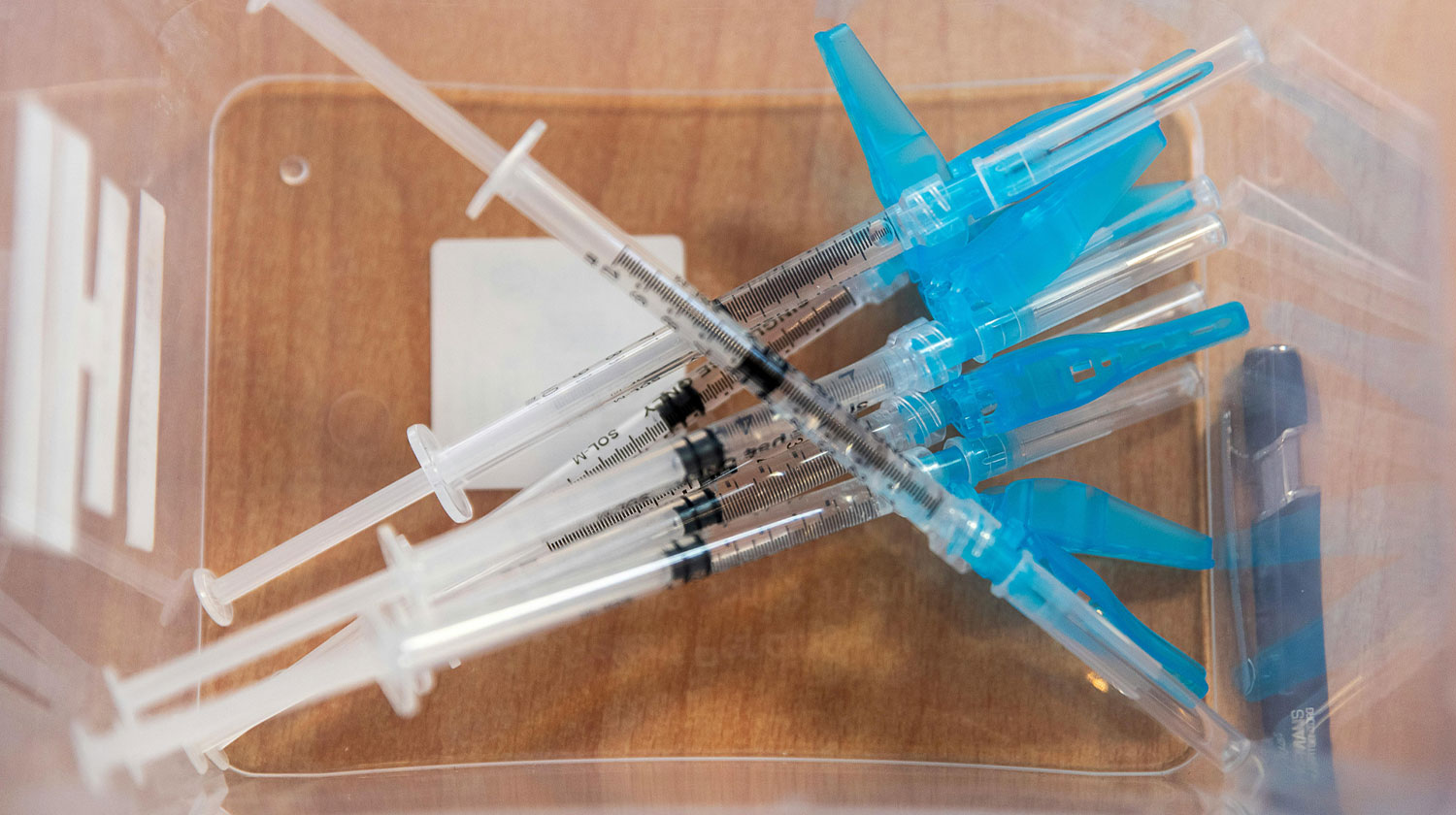

Sterilizing pre-filled syringes is far more complex than sterilizing open containers. These hermetically sealed systems contain an injectable solution and a movable plunger. During heat sterilization, the internal solution expands, releasing dissolved gases and increasing internal pressure.

If chamber pressure does not precisely match this internal buildup, the result can be plunger movement, leakage, or even expulsion which compromises both product integrity and sterility.

Traditional steam sterilizers cannot independently control temperature and pressure, making it difficult to maintain the delicate equilibrium required for pre-filled syringe sterilization. For U.S. manufacturers operating under GMP and FDA regulations, achieving sterility assurance levels (SAL) of 10⁻⁶ while maintaining syringe integrity requires technology designed specifically for counterpressure control.

The Fedegari Solution

Fedegari’s FOA Steam-Air Sterilizer was engineered precisely for these challenges. Designed for counterpressure sterilization of sealed containers such as pre-filled syringes, vials, and parenterals, the FOA uses a controlled mixture of steam and air to allow independent regulation of temperature and total chamber pressure throughout every phase of the cycle.

This fine-tuned control compensates for the internal conditions of each syringe, preventing plunger displacement, leakage, or deformation. Magnetically driven fans ensure uniform heat distribution and a consistent sterilization environment safeguarding both drug efficacy and container integrity.

Every FOA system is powered by Fedegari’s Thema4 process controller, which enables labs to develop or modify sterilization cycles with precision.

Thema4 is pre-validated to GAMP5 and 21 CFR Part 11 standards, simplifying qualification and integration with SCADA or other higher-level systems.

Built from 316L stainless steel with FDA-compliant gaskets and magnetic drives, the FOA delivers reliability and meets U.S. standards including UL 61010-1, NFPA-79, ASME BPE, and GMP.

Results

By maintaining total control of temperature and counterpressure, the FOA ensures:

- Consistent sterility assurance (SAL 10⁻⁶ or better)

- Prevention of product deformation and plunger expulsion

- Compliance with FDA and GMP standards

- Preservation of syringe content

Fedegari’s FOA series redefines precision in PFS sterilization, ensuring safety, compliance, and quality in every batch.

Partnering for Precision

Every syringe, formulation, and container presents unique sterilization challenges. Fedegari collaborates closely with U.S. pharmaceutical and biopharma labs to develop and validate tailored sterilization cycles.

Our experts run tests with various load types, materials, and process parameters to determine the optimal treatment solution for your application. From feasibility studies through full-scale qualification, Fedegari ensures every sterilization process achieves uncompromising performance, safety, and compliance, protecting both your product and your reputation.