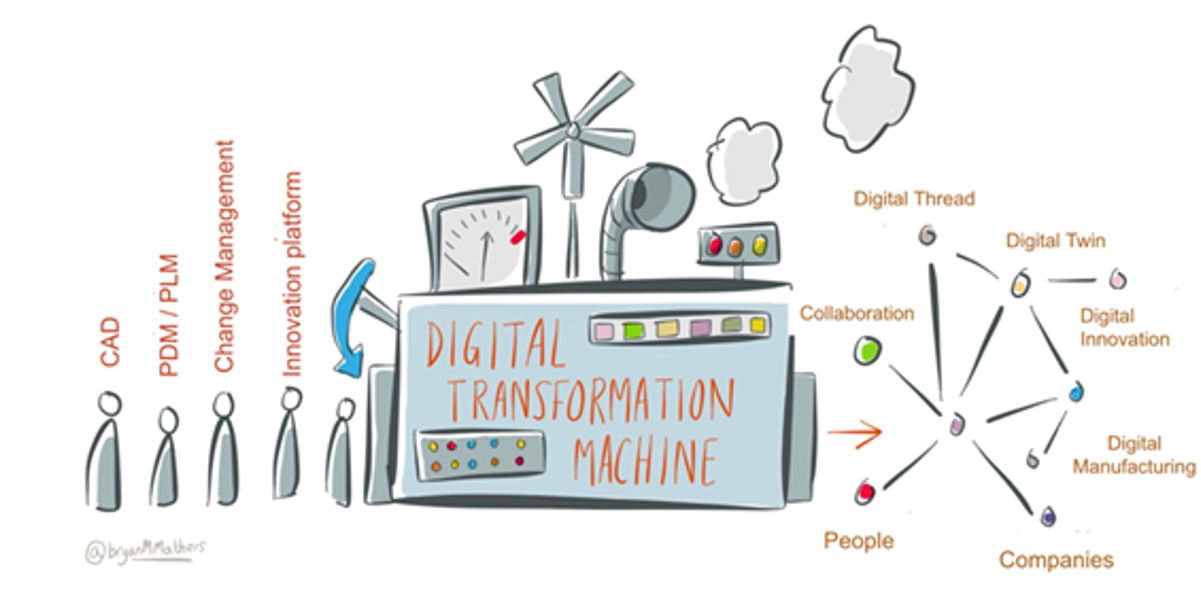

We should not be surprised, digital transformation has turned into a categorical imperative for all kinds of organizations and industries. There is no better time, no important moment to understand the effects to the secular digitalization trends we are witnessing and facing. Now is time to understand how the relentless advancements of digital technology power and persuasiveness impact corporate strategies, business models and the current and future shape of competition”, extracted from the Organization Committe Letter – University of Pavia.

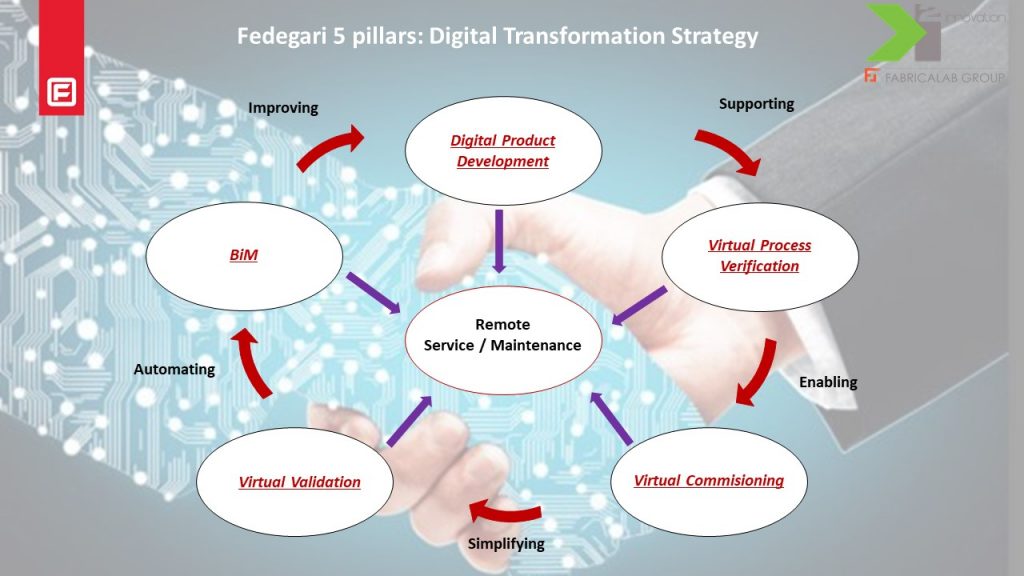

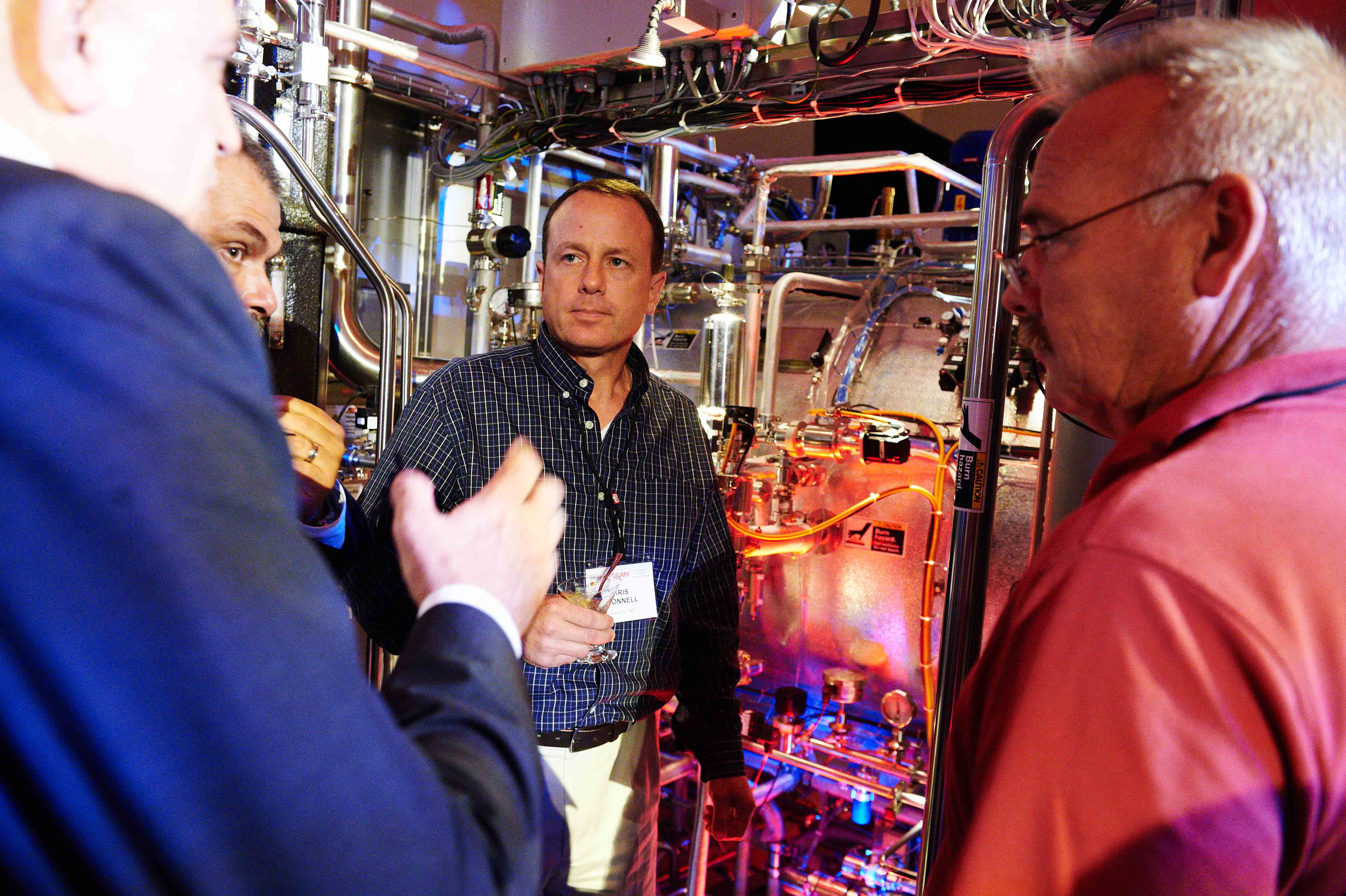

Our Global Plants Director, Marco Gonnella and Edoardo Collalto, CEO of K2innovation srl will present “The relationship between digital transformation and international business”. They will talk about the importance of the digitalization in a global company and its adoption within Fedegari Group through the support of K2Innovation.

Director, Global Plants - Fedegari Group

The identity of the end-to-end process – going through concept, design, manufacturing, installation and validation – is what makes a manufacturer the best partner – especially for those companies who privilege in-house production. Virtual Commissioning, Digital Twin, BiM and Virtual Validation have changed the identity of the production process by creating new contact points between the product and the customer. Thus, creating a completely new way of interaction”, states Marco Gonnella Director, Global Plants – Fedegari Group.